Thursday, December 22, 2016

Classic Workbench Plans Now Available

It's ready! Our Classic Workbench Plans are finally available. Details here.

Benchcrafted Classic Workbench from Benchcrafted on Vimeo.

Categories

Classic Leg Vise,

Classic Workbench

Wednesday, December 7, 2016

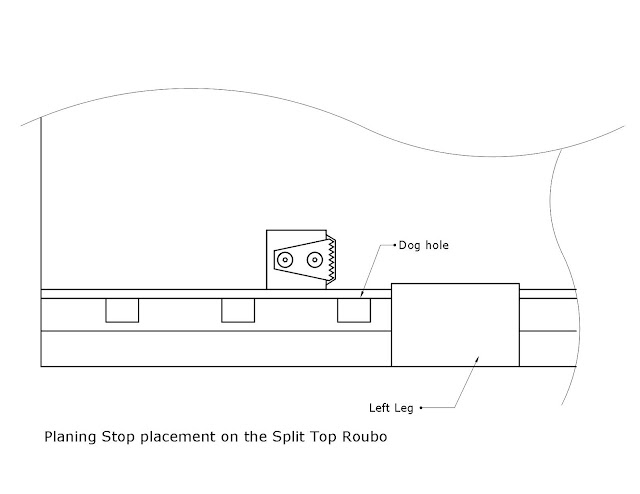

Planing Stop in the Split Top Roubo

A customer recently asked where to install his Benchcrafted Planing Stop in his Split Top Roubo, as the Split Top Roubo plans do not include the planing stop.

Here's where we recommend you install the stop: between the two dogs immediately to the left of the leg vise. You'll have to move the stop a little inboard (that is, a bit past the 2-3/4" we show in the planing stop instructions) to allow some space between the stop's stock and the dogs. We don't show any dimensions because your bench may be different. Here's the basic idea behind finding the right spot. You don't want to get the stop too close to the dogs, and at the same time you don't want it too close to the leg either so it doesn't end up behind your potentially-wider leg vise chop, making adjustment annoying.

Here's where we recommend you install the stop: between the two dogs immediately to the left of the leg vise. You'll have to move the stop a little inboard (that is, a bit past the 2-3/4" we show in the planing stop instructions) to allow some space between the stop's stock and the dogs. We don't show any dimensions because your bench may be different. Here's the basic idea behind finding the right spot. You don't want to get the stop too close to the dogs, and at the same time you don't want it too close to the leg either so it doesn't end up behind your potentially-wider leg vise chop, making adjustment annoying.

Wednesday, November 30, 2016

Hi Vise Instructions: Correction

Thanks to an attentive customer we've had to make a correction to the Hi Vise instructions. We spend inordinate amounts of time editing our plans, but evidently not enough. On page 4 we state that the Crisscross arms reside in a mortise that's 7/8" deep. But page 1 of the plans show the mortises as 1" deep.

The correct figure is 7/8" deep.

We're working on correcting the PDF and will upload it as soon as possible. In the meantime, you can download the corrected page above and print it out if you've already begun your build. If you've already cut your mortises 1" deep, don't fret. The fix is relatively easy. Simply make a 9/16" wide x 1/8" thick shim and glue it into the bottom of the mortise. That will place the bearing plates in the proper location.

EDIT: Corrected plans are now on our Downloads page.

Monday, November 28, 2016

Hi Vise Now Available

Three and a half years ago we made our first "etau" or what we now call our Hi Vise so we could take a prototype to the first Handworks event.

Now that the Hi Vise is officially for sale we can say with a bit of regret: we put this off for too long.

The new Hi Vise is quite the thing. Compact, portable, versatile. But if there's one indulgence we're guilty of with this one, its making something just because its cool. This little unit has a certain charm to it that says "lets make something fun." The other side of the coin is, it's a powerful vise that will give you the opportunity for control and precision that you may not have experienced before.

The Hi Vise is like a blacksmith's post vise for woodworkers. It gets stuff up at chest height where your eyes are closer to the work, you elbows are closer to your body, and your tools can be moved in a more efficient way. I'll never forget Peter Galbert's technique I learned during a class for how to move your body when turning a long spindle. And it sounds counter-intuitive. Begin in an uncomfortable position, and end your movement at a comfortable position. We can't have the perfect body position at all times for every operation. But we can make the best of it, which is why Galbert's technique is perfect. The Hi Vise puts detail work in that zone of comfort that you can't get with regular bench vises. Once you work at chest height when the task demands, you'll never monkey around with anything less. On a personal note, my Hi Vise (yes, I got the first one off the line) is either on the right end of my bench, or sitting below on the shelf, ready to mount at a moment's notice.

One application of the Hi Vise we haven't touched on much during development: as a permanent leg vise in its own right. It's 5 -1/2" capacity between jaws is more than enough for typical furniture making requirements. And it's robust construction (overbuilt, as we like it) means it can hold its own in more demanding situations. Although we don't recommend it for a full-on bench build, we can't think of a better leg vise for a small detail bench, or even a children's bench. The Crisscross Nine's diminutive size would also allow the Hi Vise to be built into short assembly benches as well, or even height-adjustable benches like the Noden Adjust-a-Bench.

Two Ways To Buy

The Hi Vise can be built in a number of ways (see our assembly and construction notes for all the details) but for purchasing purposes, we're offering it two ways: The Hi Vise and The Hi Vise with Mounting Screw. The Hi Vise can be built to mount your bench with clamps, holdfasts, in our Tail Vise, or in a traditional moving-block tail vise. If that's how you'll use the vise, simply purchase The Hi Vise for $189.

Here's what you'll get in the Hi Vise box (plus a few fasteners and Crubber):

All you need to complete your build is wood.

If you'd like to build the version that allows you to quickly mount the vise to any surface without tools, clamps, holdfasts, etc. you'll purchase the Hi Vise with Mounting Screw for $259. You'll get a box with the Hi Vise, plus another, separate box with this inside:

The fasteners needed to assemble the Mounting Screw are included in the hardware kit in the Hi Vise box. Again, all you'll need to complete your build is wood.

To read more about the Hi Vise, see our Hi Vise page.

To download the assembly and construction notes, click here.

To order your Hi Vise, see our store page.

Friday, November 25, 2016

Hi Vise plus minor website update

Come Monday we should have our new Hi Vise available via our Store page.

Also, a major upgrade for us but a minor one for customers; a new cart system. Our old cart worked fairly well but it could not calculate shipping costs for weighty items. This worked OK for smaller orders, but alas we flipped a coin over 10 years ago, which would it be, high end thimbles or vise hardware? The thimbles lost out to the vises and hence the widely varying costs of shipping heavy cast iron to various parts of the country and the rest of the world.

Many of you know that our kludged solution all these years has been to issue a shipping invoice after the fact. We did this primarily to save our customers any unnecessary expense, but at the cost of time and energy to us (setting a flat rate cost would have been super easy for us but would have resulted in some pretty gross over payments for our coastal friends). The downside of course, other than the extra work, as many of you also know, is that very often the additional invoice would cause confusion "I already paid, why am I being charged again...." and more often than not the invoice would go straight to spam resulting in some serious shipping delays.

So come Monday the new cart will be live. It will probably cause it's own flavor of problems (hopefully not) but we'll get them ironed out in good time. So far it's working perfectly in testing.

The rest of the website is also currently in full face lift mode, but it's going to be a little while yet.

Monday, November 21, 2016

Hi Vise Update: Video

We're still extremely busy this year trying to make good on our promise of releasing all of our new products before the snow flies (sorry folks in Northern Minnesota.) Last week we finished up the photo shoot for the Hi Vise and Classic Workbench, and here's a short video of the Hi Vise showing the different configurations it can be built in. We don't show much of the workholding capabilities because we know our supporters are highly intelligent people. This is, after all, just a leg vise. And we've made a few of those over the past decade. The function is sort of obvious. We're still holding wood the same way, just in a different position. Like all of our products, we use these daily to make stuff. It's not just another tool for us to sell.

Pricing has been nearly finalized and packing day is set for later this week, barring any unforeseen complications. If you missed out on our run of Carver's Vises back in 2013, you'll be pleasantly surprised by the Hi Vise. For nearly identical functionality, and equal cool factor you'll be able to pick up a Hi Vise for less than half the price of our Carver's vise! We really don't design our vises to meet a price point, but we do try to keep unnecessary costs down when possible.

Watch for these to become available for purchase very soon.

Wednesday, October 12, 2016

In Our Store: Crubber

Crubber is a composite material made by grinding natural cork and natural rubber, then combining the materials under great pressure to form a tough, resilient, grippy matrix that is then sliced into sheets. Crubber has become our favorite non-slip, super-grip material for lining vise jaws. Eventually, all Benchcrafted vises will ship with Crubber.

What's the advantage over suede or other cow skin-type material? It's mostly on the manufacturing end, which translates into less waste, and that means Crubber is a little less expensive than suede. It also means we're making less stuff that ends up in the landfill. We hate throwing stuff away as much as the next person.

What about grippy-ness? Crubber is excellent. Every bit (and perhaps moreso) as grippy as suede. Since the ratio we use contains a fair amount of rubber, it's also very resilient and durable. Crubber-lined vise jaws should last for years under normal use.

Attaching Crubber to your vise

You can use any glue you'd like to attach Crubber to your vise. We've tested liquid hide glue, yellow carpenter's glue and contact cement. Contact cement is nice in that it likes to peel or rub off (with a bit of effort) when it's time to replace the Crubber. The other glues will have to be scraped or planed off, or removed with hot water, although they do provide a little more holding power than the cement. Bottom line, they all work fine. Make sure you use plenty of glue, especially at the edges.

Other uses

Crubber can also be used to line the faces of your bench dogs for a non-marring surface, the faces of your clamp heads, the bottoms of shooting boards and bench hooks for a non-slip grip. We've even had customers who use Crubber as a strop. The material loads honing compound well, and has just enough drag and give to make a great strop. We also use loose sheets of Crubber to hold odd shaped pieces in our vise jaws. It also makes an excellent material to line drawer bottoms.

Crubber is available in two sizes:

8-1/2" X 11" $7 ea.

Good for leg vise jaws, or for cutting up and using for smaller surfaces.

6" x 36" $15 ea.

Large enough for Moxon vises, or twin screw vises.

Crubber is available through our store page.

Tuesday, October 11, 2016

In Our Store Now: The Benchcrafted Planing Stop

The Benchcrafted Planing Stop is now available to order. Click below for details.

The Benchcrafted Planing Stop

Aaron Moore's Compact Bench

Aaron Moore of Walke Moore Tools sent us pics of his bench that he built for demoing tools at woodworking shows. It was sized to fit in the back of the Walke Moore Tools show van.

Moore's bench is a good example of a short, simple bench that is quick and easy to build. Only 72" long, with a 2 1/2" thick top, about the only thing we'd change is to add a planing stop. And with our's available in the next day or so, Aaron will have his chance (hint!)

The bench features our Glide M, and a very understated yet classy black milk paint finish on the base and chop. We especially like the patined arris on the chop, with the hard maple showing through. Gives the bench a bit of the vector graphics look (Vectrex anyone?)

Hope you bring the bench to Handworks next year, Aaron.

Categories

Classic Workbench,

Glide Leg Vise,

Split-Top Roubo

Thursday, September 22, 2016

Fall Update

We apologize for not updating the blog as frequently, but it's been quite busy here this summer what with all our new products coming down the pike. Here's what's happening at Benchcrafted.

Swing Seat

The patterns are done and on their way to the foundry. Next week we hope to get some video of the first pour. We always run samples to check gating (how the metal flows) and such, so this won't be a production run. If the sample run looks good we'll go right ahead with a production run so we can get these produced asap. The goal on these is to have some ready for Christmas delivery.

Planing Stop

We've got the first run finished and ready for packaging. Once we update the website you'll be able to buy one. Price: $24. Includes everything you need to put one in your bench, except for the wood stock. Watch for these in the next few weeks.

Classic Workbench Plans

The plans are finished (thanks Louis!) All we need to do now is sit down and write the instructions, take some pictures and update the website. Christmastime is our goal.

Hi Vise

We've finished our first mass run of Hi Vises. This week we'll begin packaging them up. We've still got a bit of stuff to do with instructions and website copy, but we're close. We're also building the portable version this week, so look for updates on that as well.

Turbo Ecabulator

This never gets old

Categories

Classic Workbench,

Hi Vise,

New Products,

Swing Seat

Thursday, September 1, 2016

Handworks 2017

Well another 2 years will have past when this rolls around. We can now say to all you who have been asking "yes, there will be another Handworks". We're never quite sure so the answers are few (zero really) and far between.

What started out as a woodworkers version of a Bluegrass impromptu jam session out in the woods has grown just a bit (now over 50 vendors) but remains exactly the same otherwise. The event has expanded into a few more vintage buildings, other than that it's still free, homegrown, decidedly noncommercial, and low key.

We hope to see many of you there.

http://www.handworks.co/

Special thanks to Steve Thomas who was largely responsible for the 2017 poster seen above. Stevethomasart.com

Also a thanks to www.k-type.com for some font help.

Monday, August 22, 2016

Moxon Vises Now Shipping With Crubber

So we've looked for other options. And we found it in an unlikely place. Over the winter we fixed up our '69 Volkswagen Beetle and even went so far as to rebuild the engine from scratch. When we opened the gasket kit we found this corky-looking material that seemed to grip to any surface. After a fair amount of research we've sourced this material--a blend of natural cork and natural rubber, chopped up and reformed under great pressure into a dense roll of grippy material that's sliced--rotary veneer-style--into 3/32" sheets of grabby goodness. We've replaced all the suede in our shop with Crubber and we're loving it.

We'll also be offering Crubber ala carte so you can line your other vises or clamp heads. It should also work on holdfast pads, although we haven't tested that yet.

Eventually, when we run out of our stock of suede leather, all vises will ship with Crubber.

Watch for ala carte Crubber on our website this fall.

Say it one more time....Crubber!

An Elegant, Simple Bench in Walnut

Craig Thibodeau of CT Fine Furniture recently sent in these pictures of his minimalist split-top workbench in walnut, featuring our Glide C leg vise.

"Here are the photos of my split top Roubo with your vise hardware. It's not quite as clean as it was a few months ago but it has been serving me well and is naturally starting to show some of the inevitable marks of regular use. Best thing I've done for my shop in a long time."

Craig had the following to say about his bench, from his Instagram:

"And of course the main feature of this space is my split top Roubo bench with the @benchcrafted criss cross leg vise. I still find it amazing how useful this bench/vise combo has been over the past few months. I'm glad I waited so long before building a bench so I could really fine tune it to my way of working.

I'm definitely not a proponent of making a workbench as your first woodworking project. I think you need to get some time in doing some woodworking first so you can learn what type of work you want to do and how you like to work. Plus building a good quality bench is not a beginner project, it's big and heavy and takes big equipment to prep the materials properly unless your a hand tool only guy. Just my opinion of course."

"Since I had the camera out I took a few more pictures of my Roubo bench just for fun. Here's a decent shot of the @benchcrafted criss cross leg vise hardware. I'm still amazed how well the leg vise works, especially when combined with the sliding deadman. Super strong holding of workpieces with almost no effort, on my old vice I had to crank down on the handle to hold parts tight but with this one just a light turn of the handle locks pieces in place. That and the hardware really does look kind of cool. I sprayed my handle/wheel with flat black paint before assembly and left off the wooden ships wheel knobs it came with, they didn't seem necessary to me. No affiliation with Benchcrafted of course but I do like their hardware."

Don't let the simplicity of Craig's bench fool you. Craig is a master furniture maker, which makes the simplicity of the bench so satisfying. Many beginning woodworkers struggle with the minutiae of bench design, not knowing exactly what they want in a bench and vises. And that's where our bench plans come in. They've all been vetted by furniture makers with decades of experience. So chances are, if you've not got a lot of experience, building one of our benches will all but guarantee satisfaction.

But we don't want to make this post about us. So enjoy this video of one of Craig's pieces.

Categories

Classic Workbench,

Glide Leg Vise,

Split-Top Roubo

Thursday, July 21, 2016

Mid Summer Update - Hi Vise

Right now the giant fireball is roaring outside and the heat index is 116. But our test shop window air conditioner (circa 1995!) is pulling overtime and keeping it a crisp 68 degrees. In this environment of extremes the first production version of our new Hi Vise was born.

First off, we've decided to ditch the French name and stick with something simple. Hi Vise. It's a mix of sappy happy greeting and functional description. Besides, when you work at Benchcrafted you end up saying Crisscross, Glide, and Moxon about a bazillion times a day. I'm not saying "ehtoe" any more than I have to (apologies, Mr. Punchinello.)

Pricing

Okay, we still can't be 100% on this, but here's a solid ballpark. This shouldn't change much, but don't hold us to that. When we began developing this vise we touted it as having nearly all the functionality of our carver's vise, plus a couple distinct advantages over the carver's vise. That vise cost $379. The Hi Vise base model (no mounting hardware) should come in somewhere around $165, and the deluxe model (mounting hardware included) should add about $75. We're trying some new processes with this vise that give a more worn-in look such as wheelabrating. Combining this technique with precision milled surfaces makes for a sweet classic look. Our mini Crosscross arms (see above) use this process.

Base Model

The difference between the base model and deluxe model is in the mounting. The base model can be mounted in a variety of ways depending on how you build the vise. So far our favorite way is to build a bracket into the rear leg that slips down into the jaws of our Benchcrafted Tail Vise. This thing is so rock solid in this configuration you'd think the vise was part of the bench. And it mounts and dismounts nearly instantly.

Another way to mount the vise is with a simple stick of wood across the back of the rear leg. Dirt simple and quick, you can hold this vise down to your bench with a pair of holdfasts or a couple clamps. Both of these mounting blocks are attached to the rear leg of the vise with two 5/16" flat head cap screws--the mounting bracket is tapped to receive these machine threads--a technique we've long recommended.

Capacity

Typical builds will yield about 5-1/2" between the jaws at full extension.

You may notice a new material lining the jaws on this vise. For some time we've experienced increasing difficulty sourcing suede on a regular basis. The problem isn't so much supply, as there are plenty of cow hides out there, but rather finding a supplier who is consistent and wants to do business. Must just be the industry. So we've looked for other options. And we found it in an unlikely place. Over the winter we've been fixing up our '69 Volkswagen Beetle and even went so far as to rebuild the engine from scratch. When we opened the gasket kit we found this corky-looking material that seemed to grip to any surface. After a fair amount of research we've sourced this material--a blend of natural cork and natural rubber, chopped up and reformed under great pressure into a dense roll of grippy material that's sliced--rotary veneer-style--into 3/32" sheets of grabby goodness. The good thing is, it's less expensive than suede and the supply is much more reliable. As a result we'll also be offering this material, which we're tempted to call Crubber, as an item on its own so you can buy it and line your other vises or clamp heads. It should also work on holdfast pads, although we haven't tested that yet.

Look for the Hi Vise to be available this fall.

And in case you were curious about the outcome of our little VW engine experience....

Thursday, June 30, 2016

Just NONE Left: Classic Leg Vise Unfinished + more M Series Moxons & BC Holdfasts

We have just

M series Moxons still in stock. We may never do another run of these, so remember they are limited editions. Here...

As always our hand forged holdfasts come and go. The latest batch still has a few left.

Here...

Thursday, June 23, 2016

Update: French Oak Roubo Bench Kits

UPDATE: We just heard from Bo, and he's got a French Oak bench kit ready to ship. Serious inquiries only. There are no surprises here, prices are listed below. If you'd like it, contact us and we'll give you the details.

Nobody ever looked forward to leftovers. Until now.

In the year-long preparation for FORP II we prepared extra materials and hardware in the event of something catastrophic. Thankfully, nothing happened (even with Raney shuffling slabs around.) The good news is, we've got enough of everything left over to put together four complete bench kits. And we're offering them for sale here.

Here's what's included:

- 6" thick French oak to build a 2 or 3 piece top, between 96" and 108" long, and between 20" and 24" wide. We saw the slabs for good yield, but some edges could have up to 20% wane, which can be positioned on the underside of the top. The variability in the length and width is dictated by the slabs as they come off the flitch. Some are 20' long, others are 18'. Sawing off the worst of the end checks yields 96"-108" tops. We'll run the tops through the Oliver Straitoplaner which will leave minimal work before gluing up. These are processed exactly the same way as the tops we prep for the FORP.

- 4" x 6" thick French oak for the legs.

- 2-5/8" x 6" French oak for the chop.

- 2" x 4-1/4"French oak for the rails.

- 4/4 French oak for the shelf boards.

- 3x3 French oak for the planing stop.

All the above will be sawn to nominal dimensions, which you'll then work to S4S in your shop.

- French Oak Plate 11 Leg Vise

Massive French oak screw and tapped leg by Lake Erie Toolworks

Wrought iron ring ferrule hand forged by Peter Ross

Wrought iron vise handle hand forged by Peter Ross

Crisscross Solo by Benchcrafted

- Plate 11-style holdfast hand forged by Benchcrafted

- Plate 11-style planing stop hand-forged by Peter Ross

The entire package will be strapped to a robust pallet and carefully prepared for truck shipment to your shop. Pickup in Barnesville, GA is also an option.

This is everything that the FORP participants received during the build last week, except for the letterpress label and lunch. If you want a FORP bench, but couldn't make the build, this is your only chance to get this kit.

The price for the kit is $4410.

Actual freight costs, which range around $300 (that's a wide average) will be added at the time of shipping (unless you're picking up.)

Again, we only have

If you're interested in buying a kit, drop an email to info@benchcrafted.com and we'll tell you how to pay.

Monday, June 13, 2016

The Big Bench Seat Update

Here's an update on new things we're working on, in particular, our new swinging bench seat. As an aside, the blog has been a bit slow here lately, but it's not for lack of content. We're simply busy with four new products that are demanding much of our attention. If you've not followed our Instagram page, you may want to peek in now and then. We've found it an excellent medium for sharing quick snippets that are just too short for a blog entry.

Development on the bench/swing seat (we don't have an official name yet) is moving forward at a steady pace. We're through with the prototyping and design stages and are in the midst of fabricating and mounting the two patterns for the seat on our foundry match plates, one for the seat's arm, the other for the mounting bracket. After that, we do a small run of castings to check our gating and whether the molten iron is flowing into all the nooks and crannies properly.

Although simple, there are some finer points to this thing that we're going to address. But before we get to that, a few words about cost. These seats were originally used in an industrial or institutional setting. Prisons, cafeterias, schools. In other words, they were made in a rudimentary way to keep costs down and production up, since many of the purchasers were limited by tight budgets. Although we're putting a little more into our version than ones of the past, the philosophy behind the price will remain. We want these to be affordable, and the way we're designing them, they should be. If you decide you want a couple of these for different benches in the shop (or even the house) we're hoping to make that an easy decision to make.

Many of the vintage seats mount via an L-shaped bracket that attaches at a corner. This is fine for general table use, but not for a workbench. We've designed ours to mount on the side of a bench leg, leaving the front plane of the bench uninterrupted. You won't know the seat is even there once you swing it away under the end of the bench.

Another improvement we're incorporating is machined bosses. The bearing surfaces on many vintage seats are simply left sand cast, leaving a less than smooth surface. Machining these areas will guarantee smooth operation and a firmly planted feel while sitting.

Several of you have asked us about an adjustable height feature. This seat will not be adjustable, and there's a couple reasons for this. First is cost. Adding an acme screw, plus joining it to a cast seat base, and then tapping a casting for acme thread are all very expensive processes. Plus, an acme screw will also have a bit of play about the threads. This translates into axial movement, which lends a feeling of instability to the seat. Yes, it's true that threaded seat posts have been made by the thousands in the past, but for a workbench application, we like rigidity. So, although we could make an adjustable version that would function well, we don't think it's worth the added cost. Plus, we've found in our tests that the vast majority of work done while seated is done from a single height. If you need adjustability, then this isn't the seat for you.

Home use. We've been asked if this seat can be used at a kitchen island, dining table, or bar. The answer is, likely yes. We've designed this for use primarily as a workbench accessory, and have sized it for such. When sitting at a bench you want to be able to get close to your work, so we've sized the arm so the seat position places most people's thighs (and knees) even with or a bit past the mounting bracket, and thus, under the bench top. This also means the seat can be rotated out of the way when not in use. If you want to mount the seat to a table who's top extends beyond the leg (thus pushing the user away from the leg and thus the mounting bracket) a separate mounting bar must be used to, in effect, extend the length of the seat's arm. This can be made of wood. Many vintage seats incorporated a rather wide mounting bracket to serve this purpose. We may offer a separate mounting bracket, in cast iron, for just this purpose.

The hardware used to mount the bracket to your bench will be up to the end user. Since there are a wide array of leg thicknesses, we can't anticipate everyone's needs. We recommend bolts to mount, but in some cases lag screws must be used. We'll have instructions and recommendations for this.

We will not be providing the actual wood seats, at least at the beginning. Like the rest of our bench hardware you'll be expected, as woodworkers, to fashion your own wood components.

If you've got any questions, feel free to ask away in the comments.

Etau/Hi Vise

We still haven't settled on a name for this either. We're about half way through our initial production run. We're still on target for an early fall release.

Planing Stop

We've jumped through some hoops to figure out how to make these reasonably and we think we're there. These are getting the black oxide treatment at the moment. Once they come back from that facility, we'll start machining in the teeth. Yeah, they are going to be two-tone and look really wicked.

Classic Workbench Plans

Hey, you can't rush genius. We're working on them.

Benchcrafted Autonomous Vehicle

We're not making much progress on this since we like to row our own. Since we're on the topic, anyone want to buy a mint, 7600 mile 2013 Honda Fit Sport with manual? Nobody drives sticks anymore...

Development on the bench/swing seat (we don't have an official name yet) is moving forward at a steady pace. We're through with the prototyping and design stages and are in the midst of fabricating and mounting the two patterns for the seat on our foundry match plates, one for the seat's arm, the other for the mounting bracket. After that, we do a small run of castings to check our gating and whether the molten iron is flowing into all the nooks and crannies properly.

Although simple, there are some finer points to this thing that we're going to address. But before we get to that, a few words about cost. These seats were originally used in an industrial or institutional setting. Prisons, cafeterias, schools. In other words, they were made in a rudimentary way to keep costs down and production up, since many of the purchasers were limited by tight budgets. Although we're putting a little more into our version than ones of the past, the philosophy behind the price will remain. We want these to be affordable, and the way we're designing them, they should be. If you decide you want a couple of these for different benches in the shop (or even the house) we're hoping to make that an easy decision to make.

Many of the vintage seats mount via an L-shaped bracket that attaches at a corner. This is fine for general table use, but not for a workbench. We've designed ours to mount on the side of a bench leg, leaving the front plane of the bench uninterrupted. You won't know the seat is even there once you swing it away under the end of the bench.

Another improvement we're incorporating is machined bosses. The bearing surfaces on many vintage seats are simply left sand cast, leaving a less than smooth surface. Machining these areas will guarantee smooth operation and a firmly planted feel while sitting.

Home use. We've been asked if this seat can be used at a kitchen island, dining table, or bar. The answer is, likely yes. We've designed this for use primarily as a workbench accessory, and have sized it for such. When sitting at a bench you want to be able to get close to your work, so we've sized the arm so the seat position places most people's thighs (and knees) even with or a bit past the mounting bracket, and thus, under the bench top. This also means the seat can be rotated out of the way when not in use. If you want to mount the seat to a table who's top extends beyond the leg (thus pushing the user away from the leg and thus the mounting bracket) a separate mounting bar must be used to, in effect, extend the length of the seat's arm. This can be made of wood. Many vintage seats incorporated a rather wide mounting bracket to serve this purpose. We may offer a separate mounting bracket, in cast iron, for just this purpose.

The hardware used to mount the bracket to your bench will be up to the end user. Since there are a wide array of leg thicknesses, we can't anticipate everyone's needs. We recommend bolts to mount, but in some cases lag screws must be used. We'll have instructions and recommendations for this.

We will not be providing the actual wood seats, at least at the beginning. Like the rest of our bench hardware you'll be expected, as woodworkers, to fashion your own wood components.

If you've got any questions, feel free to ask away in the comments.

Etau/Hi Vise

We still haven't settled on a name for this either. We're about half way through our initial production run. We're still on target for an early fall release.

Planing Stop

We've jumped through some hoops to figure out how to make these reasonably and we think we're there. These are getting the black oxide treatment at the moment. Once they come back from that facility, we'll start machining in the teeth. Yeah, they are going to be two-tone and look really wicked.

Classic Workbench Plans

Hey, you can't rush genius. We're working on them.

We're not making much progress on this since we like to row our own. Since we're on the topic, anyone want to buy a mint, 7600 mile 2013 Honda Fit Sport with manual? Nobody drives sticks anymore...

Wednesday, May 4, 2016

Moxon M Series Available In Our Store and Hand Forged Holdfasts Too

Yesterday we spent a gorgeous spring day holed up in our packing room just because we love our customers so much. The result? We've got Moxon M Series vises packed, photographed, digitized, virtualized and webified so you can buy one. To order, see our store page.

Since many of you will wonder what's different about these, and why the price is so much higher than our standard Moxon vises, here's the low down. Over the past several years we've had many requests to offer a Moxon kit with fully machined cast iron wheels, to match the M series of vises we offer in the Glide and Tail Vise. We finally got around to making a small run. We can't promise we'll do more once these are sold out. Functionally these are identical to our standard Moxon vise. The feel of the wheel in your hand is obviously a bit different. But aside from that, no difference other than the look. The price reflects exactly the increase in machine process and labor required to take these from a sand casting to what you see above (obviously a huge amount of precision machine work, below is what we start with!) We're not upcharging these simply because they are fancier or a limited run.

We've also added our hand forged holdfasts to the store page, so you can order these more conveniently.

Monday, April 25, 2016

Production Updates For New Stuff

It's been a very busy 2016 so far here at Benchcrafted. We're up to our ears in new products that we want to offer this year. So here's an update on where things stand.

Classic Workbench Plans

We're hard at work drafting the plans for the bench. The goal is to have everything ready by the end of summer/early fall. We're trying to make these a little unique, perhaps print them on special paper, or make them look like old blueprints. We're not sure how that will play out, but we're trying hard to figure it out while keeping the price reasonable.

Planing Stop

We've been jumping over a few hurdles on this one. This is basically a really thick, but short saw. Getting nice sharp teeth in thick steel takes some doing, while keeping the price reasonable. We've got a few tricks up our sleeve though. We're looking at about 2-3 months availability on these at the earliest.

Etau/Hi Vise

Production on the vise is underway and we'll have the first components finished in the next couple weeks. We will be offering this vise in two setups.

The base model will mount to your bench depending on how you build the vise. And we'll have plans showing various ways of doing this. For example, the rear leg of the vise can be built with wings that allow you to clamp the vise to a benchtop with typical clamps or two holdfasts. Another way will be to build the vise with an arm that extends back and down off the rear leg, to allow the arm to slip between the jaws of our Tail Vise and be held firmly in position. Quick and extremely solid. Or you can simply build the vise with a plain rear leg for holding in a traditional, open-front tail vise. This will allow the vise to be pivoted fore and aft in the jaws of your tail vise. We'll cover all this in great detail.

The deluxe model will include hardware to allow the vise to be quickly clamped to any surface via a mounting screw built in to the rear leg. The mounting screw will be sized to accommodate a broad range of thicknesses, from a 4" workbench, to a 3/4" particle board banquet table (hey, you never know.) You can also build the vise to clamp to a range of thicknesses of your own choosing in case you've got a really thick bench.

Bench Seat / Swing Seat

We're still in the design phase on this one, but moving right along. It will go to the head of the line once we get further along on the Etau. We're particularly excited about this one. We've been using the heck out of our prototype, and so far everyone is saying "how did I work without this?"

Wednesday, April 20, 2016

STILL IN STOCK: Classic Leg Vise Unfinished & BC Holdfasts

Sold out......!

When we first released our Classic Leg Vise we promised a few that we'd eventually offer it without the black Parkerized finish. Here's your chance to pick one up.

We only have a limited number of these, since this isn't a stock item. First come, first served.

The vise will arrive unfinished, sporting the freshly-machined steel surfaces right off our mills and lathes. The parts will have a light coating of oil. We recommend that you treat these like raw steel (since they are) and either keep them lightly oiled, or give them a good coat of paste wax to keep the rust at bay. You could also just let them get a nice old bronzey patina, if you have a few years worth of patience. A rub down with steel wool, followed by cold bluing would give them a steel-blue sort of look. Baked flax is also an option.

The handle is the only part that doesn't get fully machined. Since we start with cold rolled steel, the main shaft of the handle shows the mill finish, with only the threaded ends, and the V-groove midway being machined. This makes the main shaft look less shiny than the rest of the vise. The solution to unify the look of the handle (if you care) is to polish it with a maroon or gray Scotch-Brite pad, followed by fine steel wool (which is what we did to the assembled handle in the background.) You can do this to the rest of the vise as well, if you like the brushed, satiny-look.

If you're building a complete bench, this would pair nicely with a Tail Vise M, with its fully-machined handwheel.

The price of the unfinished Classic is normally the same as the standard Classic.

Subscribe to:

Posts (Atom)

Made in the U.S.A.

Made in the U.S.A.