Tuesday, February 26, 2013

The French Oak Roubo Project

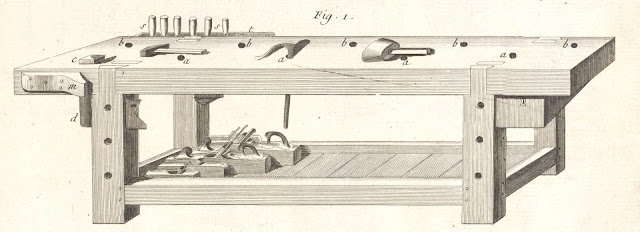

This summer, a small group of Roubo enthusiasts will gather to build the famed bench from Plate 11 of Roubo's L'Art du Menuisier.

And you are invited.

Over the past couple years and after several trips to a Roubo-esque millwork shop in rural Georgia, we've been able to source enough French oak to build several benches that almost exactly match Roubo's description of his joiner's bench from Plate 11. The slabs are 5-6" thick, from 18 to 28 inches wide and around 19' long. They have been air drying for over 10 years. But here's the kicker. Some of these trees are directly from the grounds of Versailles, and were likely growing in the late 18th century. We haven't counted the growth rings, but there's a good chance these trees and Roubo were contemporaries. Roubo could have even touched one of these trees.

The Enthusiasts

Benchcrafted - Of course, we'll be there

Daed Toolworks - Infill plane maker Raney Nelson

Jeff Miller - One of American's legendary furniture makers

Lost Art Press - Chris Schwarz, the great Roubo revivalist, will bring his extensive workbench knowledge base and bench-building expertise.

Don Williams, the headmaster of the team of translators bringing Roubo's "L'Art du Menuisier" to the English-speaking world.

Brese Plane - Plane maker Ron Brese will be in attendance.

Jon Fiant - Atlanta-area cabinet and benchmaker will lend his hand

The Concept

Building several massive benches is best accomplished as a team effort. This is not a class, but rather a gathering to build some amazing benches with some amazing material, in an amazing place. There will be plenty of help with technique should you need it, but don't expect a lot of one-on-one instruction. The purpose here is to build, and have a good time doing it. We encourage intermediate to advanced woodworkers. If you're a rank beginner, good chance you'll be in over your head, which won't be fun for you (or the rest of us.)

The Material

Slabs of this size, age and dryness are extremely rare. We never expected to find wood like this, let alone with this provenance. Roubo calls for oak for the bench legs. We've got that. 4" thick slabs of French oak. These will get sawn up for legs and rails. The wood for the tops will be cut from massively thick slabs of French oak. All these slabs are between 5" and 6" thick, and we anticipate will finish out at not less than 5". Wood being what wood is, these ideals are of course not written in stone. One thing is guaranteed. You will go home with a very unique bench, some incredible hardware, a very unique experience, and a piece of history. Wood like this comes around maybe once in a lifetime. This wood is not inexpensive, but we could not pass up this opportunity. We're so thrilled to be meeting up with the roster of enthusiasts for this build, that we're pricing the entire package as reasonably as we can. The experience here is as special as the wood.

The Location

The first time we stepped onto the grounds at Wyatt Childs, Inc. we thought we'd stepped back a couple centuries. More than just a millwork shop, Wyatt Childs imports antique wares from Europe, and especially France. The grounds are covered with everything from ancient bronze street lamps to enormous granite millstones, all completely authentic. And wood. Lots of wide, thick wood in uncommon species. Scotch pine as wide as a dining table. 14' high stacks of sequenced Chestnut. Salvaged boards from the 16th century. If you're planning to build some furniture with your new bench (naturally) you might want to bring a trailer. Bo's lumber shed is a cornucopia of lignum vitality!

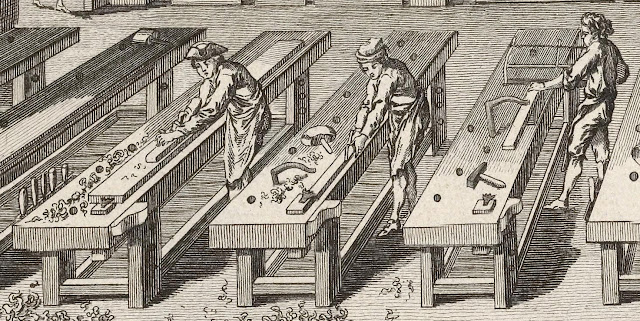

It's these items, along with the output of the millwork shop that find their way into such locales as the Doonbeg 5-star Hotel (Ireland.) But what makes Child's facility unique is the man himself. Wyatt, or Bo as he's known, is a man who loves wood. When we first stepped foot in the millwork building a few years ago, Bo was instructing his team of joiners on the fine points of assembling some Roubo-style parquetry floor panels in walnut. From outfitting high-class lodges to Manhattan condos, Bo's shop is the modern-day version of Roubo's Plate 11. We even saw a set of wall panels from a 17th century castle that Bo had rescued from the wood stove (the owner's were using them for heat.) They looked like they'd been pulled directly from a L'Art du Menuisier engraving. As we chatted with Bo, the subject inevitably moved to Roubo, and the seeds for this event were planted. After a few trips to France (and countless phone calls) two containers of French oak were crossing the Atlantic.

Child's shop is virtually tailor-made for building benches. The 36" Oliver Straitoplaner is a gargantuan power-fed jointer capable of flattening an entire benchtop at once. In addition to the Oliver, the building we'll be working in is outfitted with lots of old American iron. Northfield, Tannewitz, among others, all set in a brick and paneled wood interior with good light.

The Bench

We'll be focusing on creating the bench from Roubo's Plate 11. That means lots of mortise and tenon work, as well as the double dovetailed tenon that joins the legs to the top. Its a simple bench, with one simple vise. But don't hesitate to add your own touches, like additional vises. You are, after all, building your own bench.

The Accoutrements

The Roubo bench isn't complete without a few essential accessories: the holdfast, the planing stop, and the leg vise. Benchcrafted will be making custom leg vise screws (can be paired with a Crisscross) just for this event, based directly on Roubo's engraving (below), and master blacksmith Peter Ross will be supplying the hand-forged ring and handle for the leg vise, as well as the Roubo-style holdfast and toothed planing stop, especially for the build.

The Date

Monday July 15 through Friday July 19, 2013

The Price

$4500. Includes enrollment in the five day event, and enough French Oak to build the bench (8-9 feet long, 5+" thick, 18" to 24" wide), Benchcrafted's custom Roubo leg vise screw (with forged ring and handle by Peter Ross), Peter Ross holdfast and planing stop, and use of machinery and equipment at Wyatt Childs Inc. Attendees should bring their own hand tools and any other ancillary items they wish to use during the build (sawhorses, portable power tools--router, etc.)

Transportation, lodging, and meals are the responsibility of each participant. Participants not able to transport their bench home at the end of the week may arrange with Wyatt Childs Inc. for crating and shipping.

The event is limited to only 10 participants, and we need 10 participants to make it happen.

As of March 1, we have ten participants! Thank you to those who registered. Send us an email if you would like to be placed on the wait list.

Saturday, February 23, 2013

Carver's Vise First Look

Late last year we took delivery of about 600 board feet of 16/4 American beech, and its from that stock that I'm building this vise. Most of the billets we have are around 5-6" wide, so they are all either rift, or dead quartered. This piece is quartered.

On the original vise the front half of the chop is joined to the base with giant through dovetails. The front chop is 2-1/2" thick, and the base in 2-1/8" thick. I used the same technique that I use for joining end caps to front laminates on benches. This joint is a tad easier though since they are not half-blinds. Working with the American beech is a ton of fun. It's not the most cooperative wood, but its close. There is something about beech that just says "hand tool".

The base of the vise features an access hole for the mounting screw and two steel wear plates for durability and smooth repositioning under the head of the mounting screw.

To mount the vise to the bench, the square head of the mounting screw passes up through a square mortise in the base. This allows the mounting screw to stay in place on your bench at all times (recessed flush in another square mortise in your benchtop), and makes the vise quick and easy to mount and dismount.

The head of the screw slides smoothly on the steel wear plates as you pivot and reposition the base.

A shallow ramp at the end of the cover plate's mortise allows the cover plate to be removed quickly and easily with a simple press.

Like this.

The mounting screw passes through a 3/4" hole in your bench (or in this case a dog hole) and engages with a nut in the form of an iron handwheel. A large and thick steel washer provides a substantial bearing surface for the handwheel.

The screw length is generous, and long enough to accommodate very thick workbenches.The thread pitch is such that the wheel holds the vise very securely without having to crank down on the wheel.

For demonstration purposes we filled the logo with white enamel.

Stock vises will most likely be supplied with unfilled logos (above), although that's not set in stone.

We haven't quite figured out pricing on this vise yet, but we're close. Unlike our other vises, we're offering this vise in a limited run, so once this batch is gone we may or may not make another batch, depending on how these sell.

A limited number of 16/4 beech billets (enough to build one vise) will be available for purchase.

Update: We've been getting a lot of emails in response to this posting. Right now we don't have a wait list, or pre-ordering. When we have details about pricing and availability we'll give a head's-up here. If you have technical questions about the vise itself, feel free to post them below in the comments section and we'll be glad to answer them.

If you'd like to see this complete vise, we're planning on bringing it to the Lie-Nielsen Hand Tool Event next weekend (March 1-2) in Kansas City.

Subscribe to:

Posts (Atom)

Made in the U.S.A.

Made in the U.S.A.